Joyce Uses 3D Printing Technology for Everyday Innovation

The engineering team at Joyce is constantly looking for ways to make our manufacturing processes more efficient and to give our customers a competitive edge.

A recent driver of innovation at Joyce has been the introduction of 3D printing technology, which we use for many different applications such as prototyping machinery parts and testing new foam moulds.

We spoke to our mechatronics engineer Daniel Lowe about how we use 3D printing technology and why it’s good for Joyce and our customers.

Tell us a bit about the machinery and technology involved

3D printing, or additive manufacturing, is a process of making three dimensional solid objects from a digital file.

We utilise two different types of printing technologies.

One is a fused deposition modelling (FDM) style printer, which is the most common. It uses a roll of plastic which is melted by a hot end at around 200°C and forced through an extruder. After this process, it cools and re-solidifies to create the part we need.

The other technology we use is a resin-based printer. This uses ultraviolet (UV) light to cure and solidify a UV-reactive resin. After each layer is cured by projecting a 2D image on the surface of the resin, the resin is replenished over the top of the part and a new layer is cured onto the previous one.

By curing each layer one at a time, a 3D part forms. This method is much faster than traditional FDM printing, however, it comes with its own challenges which must be carefully controlled and accounted for by the production team.

What’s your particular interest in using 3D printing at work?

3D printing is a fairly old technology. It’s been around since the 1980s. However, it only recently became widely accessible as patents expired and more designs and developments became open-source.

I purchased my first 3D printer four years ago and began designing and printing parts at home for various needs.

When I started working at Joyce, the company recognised the potential for 3D printing to help in the development and production of niche and bespoke solutions for our customers.

Tell us about how Joyce uses 3D printing

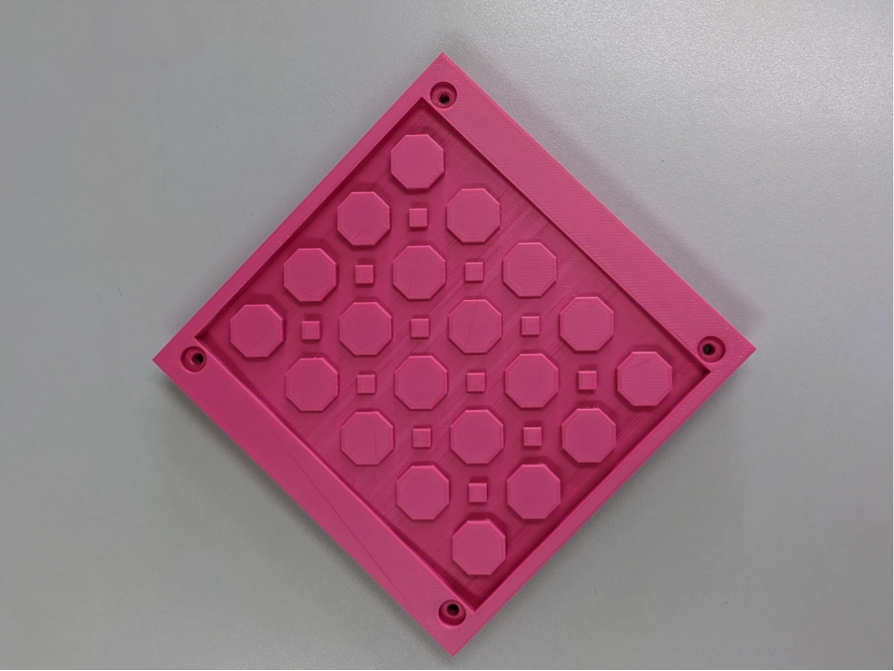

One of my first projects was to examine how we could use the technology for rapid prototyping of moulds for our Pressure Cutting Machine. Traditionally, large boards are CNC cut to provide a template for the machine. Each template can cost upwards of $2000.

Traditional CNC board template

With rapid prototyping on a 3D printer, we’re able to test concepts and patterns which would have been prohibitively expensive to test using traditional means as they require multiple iterations to perfect.

For less than $100, we’re able to design, print and test multiple templates to achieve the perfect, customised solution for each customer.

3D printed test mould

We have also used 3D printing to print customised parts for some of our machinery and equipment. This helps ensure that the factory continues to run smoothly and efficiently.

What are the key advantages of using 3D printing both for the company and our clients?

3D printing is a lower cost alternative to traditional manufacturing. It can offer levels of detail and complexity in design which would be unachievable using other methods.

It allows us to test concept designs quickly and easily. It means we can give our customers an indication of our cutting capabilities without a large initial outlay for full-sized templates.

It’s a great way to help our clients visualise new products during the development process.

We’ve also used 3D technology to develop new templates for furniture and bedding designs, particularly pillows and cushions. Being able to integrate company logos and product and company names into these templates is another way we help our customers create differentiated, customised products.

To find out how you can take advantage of Joyce’s 3D printing capabilities, contact Customer Service at 1800 021 304 or email sales@joyce.com.au.